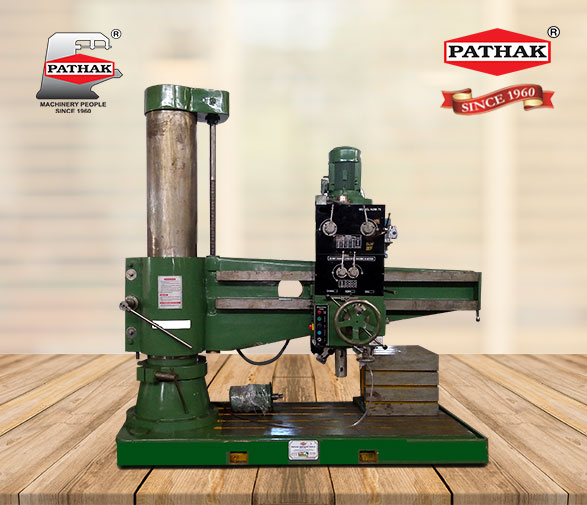

All Geared Radial Drill Machine

"Pathak Machine tools an ISO 9001:2015 certified company"

Contact NowLeading All Geared Radial Drill Machine Manufacturers In India.

The machine is equipped with a gearbox that’s oil bath oriented and is more effective than the all geared radial drill machine that comes with the grease lubrication functionality.

The grease one provides less cooling than the oil, while this machine is best suited to provide you continuous duty with heavy loads at faster speeds. The machine made by all geared radial drill machine suppliers in India will suffer less power loss and will provide you the right power you require in works. Apart from this, the machine runs with a single gear that will save your gear changing time and can give you the right production.

Premium Quality Tools And Products

Pathak Machines Leading Suppliers of All Geared Radial Drill Machine.

We have introduced machines with the latest technology for the better promotion and production of the work with easy compatibility and user skills.

Pathak Machines, assures you the quality of the machines. One of the leading milling machine manufacturers which is superior in providing durable, premium quality tools and products.

Features Of Our Product

Different kinds of the features of the machine given below:

- Machine over All Casting Material Is High-Quality Closed Grain Casting.

- All the Gears Is Made of 20mn-Cr-5 Material and Hardened & Grinding Finish.

- Lifting Screw Nut and Auto Feed Worm Gear Is Made of Bronze Metal.

- Time Saving & Rapid Production Due to Single Gear Changer.

- Every Gear & Friction Feed Gear Is with Bearing Fitted.

The all geared radial drill machine will serve you best when you are trying to have a hole in material, but you don’t want to cut off the power when the work is over. The machine will simply cut off the force for you automatically once the work is done. This will not only be safe to use but also will save your electrical power so you can have minimum operational costs. Simply utilise the high-quality Pathak Machine and grow your business like never before.

The device is convenient for the drilling of heavy work pieces and the loads that are porous. You can also use it for construction activities, transportation functions, medical equipment manufacturing, and more.

TECHNICAL SPECIFICATIONS OF ALL GEARED RADIAL DRILL MACHINE

| Sr.no. | Specifications | Model RD-75 | Model RD-65B | Model RD-50B | ||

| 1. | Drilling Capacity In Solid Mild Steel | 75 mm | 65 mm | 50mm | ||

| 2. | Drilling Capacity In cast Iron | 85mm | 75mm | 60mm | ||

| 3. | Dia. Of Column | 405mm | 355mm | 310mm | ||

| 4. | Drilling Radius Minimum | 675mm | 650mm | 450mm | ||

| 5. | Drilling Radius Maximum | 1950mm | 1600mm | 1100mm | ||

| 6. | Machine Height from Floor | 3320mm | 3170mm | – | ||

| 7. | Distance From Spindle Nose Top Of The Base Plate Minimum- Spindle In Downward Position | 100mm | 100mm | 100mm | ||

| 8. | Distance From Spindle Nose Top Of The Base Plate Minimum- Spindle In Upward Position | 1750mm | 1600mm | 1300mm | ||

| 9. | Drilling Depth | 325mm | 325mm | 225mm | ||

| 10. | Working Surface Of Base Plate | 1735 x 940mm | 1460 x 845mm | 975x655mm | ||

| 11. | Dimensions Of Base | 2640 x 1110 x 210 | 2370x1015x210 | 1645x835x200 | ||

| 12. | Effective Area Of Box Table | 600 x 450 x 450 | 600x450x450 | 550x400x400 | ||

| 13. | No. Of Spindle Speeds & Range(RPM x Steps) | 20-740 x 12 Steps | 25-930 x 12 Steps | 40-790 x 9 Steps | ||

| 14. | No. Of Spindle Feeds Of Range | 0.10-1.25 x 6 Steps | 0.10-1.25 x 6 Steps | 0.080-0.180×3 Steps | ||

| 15. | Taper Spindle Nose Socket (Per Rev / Steps ) | MT-6 | MT-5 | MT-5 | ||

| 16. | Main Motor | 7.5 HP | 5 HP | 3 HP | ||

| 17. | Elevating Motor | 5 HP | 3 HP | 2 HP | ||

| ***Machine’s pictures shown in the offer are for reference only. | ||||||

| **PATHAK follows a policy of continual improvement of design & we therefore reserve the right to supply the machines differing in detail | ||||||

| from that described herein. | ||||||